.

Frequently Asked Questions

Why Is

PunctureSafe Beneficial in a Tyre?

The majority of flats and blow-outs are a result of driver negligence. The number one cause being excessive heat generated from under inflation. The overheated, under inflated tyre becomes soft and can be penetrated very easily. However, under inflation creates additional problems such as tread and ply separation, all of which is primarily caused by porosity (natural air migration) which exists in all tyres to some degree. PunctureSafe eliminates air migration and prevents the majority of damage created by under inflation, thereby preventing most related blow-outs. Once Puncturesafe has been installed, it conditions the tyre making the rubber supple, thereby helping to reduce sidewall cracking, deterioration, and porosity.

Heat in a tyre is critical, because it helps with traction (helps the tyre stick to the road) but excessive heat is a major problem. Heat on the outside of the tyre caused by contact with the road eventually makes its way to the inside causing hotspots, but because rubber is a poor conductor, very little of this heat makes its way to the rim, which is a wheels natural heat sink. Eventually, this heat inside, builds up, causing punctures, blowouts, excessive tyre wear, and eventual failure. This is where PunctureSafe can help. The PunctureSafe treatment deals with this heat in two ways, it disperses then conducts the heat to the rim, via Puncturesafe’s liquid inner tyre coverage, and also due to the fact a little of the secret liquid polymer formulation within the product vapourises whilst the vehicle is in motion, and the heat from this vapour is transferred by condensation to the rim with contact, where it is then passed to the outside environment. What you have now, is a perfectly performing tyre, which has the correct temperature on the outside to maintain traction, and cool on the inside, which will help stop tyre failure and help extend tyre life considerably.

Puncturesafe’s proprietary process does not use any glue to make a seal, so PunctureSafe is the answer to the problem of the patch that fails due to excessive heat. On the contrary heat is very beneficial to this process, therefore the seal cannot fail due to heat. If the casing becomes damaged or weakened to the point of being unsafe, the PunctureSafe formulation has been designed to slowly bleed regardless of how small the puncture may be, giving a controlled deflation. Cords are instrumental in rubber recovery, and without cords a tyre will blow up like a balloon. When cords are severely cut, the hole in the tyre will enlarge with increased air pressure, so in a moving vehicle, PunctureSafe will assist to give this controlled deflation as the hole shrinks with increasing air loss and reducing air pressure. With Puncturesafe, and a controlled deflation, a tyre will deflate at a rate depending on the extent of the damage, then as the tyre reaches the lower pressures of 10 to 15 psi, a severe slow down or halt in air loss will be experienced as PunctureSafe’s unique formulation and synthetic fibres are now log jamming in a puncture that is now shrinking in size because of these much lower air pressures. You could now be running on a soft tyre instead of the wheel rim, which could mean the difference between keeping control or losing control. This is possible because we do not use chopped up rubber tyres in our formulation, we use small particle size soft rubber and 5 different sizes of specially manufactured “course surface” synthetic fibres which interlock tightly together in the puncture.

PunctureSafe’s abilities and performance is not diminished by speed, distance or time

No excessive heat, no punctures,no excessive tyre wear.

What are the Key Attributes of Puncturesafe?

Extends tyre life

PunctureSafe maintains air pressure, retards aging within the casing, reduces heat build-up and increase tyre life.

Protects against under-inflation

PunctureSafe has the ability to eliminate porosity, air migration and seepage, thereby allowing the tyre to maintain proper air pressure, which in turn will prevent rolling resistance and heat build-up, the biggest cause of high fuel consumption and tyre failure. For retreaders this also prevents the inception of most tread separations & ruptures.

Heat reduction

PunctureSafe assists in protecting tyres from devastating heat build-up, which is associated with friction caused by under inflation, and/or overloading. PunctureSafe contains specific ingredients that aid in conducting heat away from the tyre, by transmitting additional heat to the rim (which is the tyre’s natural heat sink), resulting in a cooler running tyre for any type of equipment or vehicle, regardless of use.

Safety Factor

PunctureSafe provides safety factors that are not found in any tyre. PunctureSafe will not mask or hide damage that has breached the integrity of the tyre. PunctureSafe is specially formulated to allow any serious puncture (potentially dangerous) to slowly deflate in a controlled manner. This attribute provides safety and aids in alleviating the hazards associated with blowouts. PunctureSafe cannot create a secure seal in any tyre that has major internal damage, regardless of the puncturing object’s diameter. This is because PunctureSafe needs rubber recovery in order to work effectively. Cords play a vital part in rubber recovery, but in a puncture that has damaged cords puncturesafe and air will slowly bleed out of the tyre giving the driver a controlled deflation.

Lasts the life of the tyre

PunctureSafe’s proprietary process protects the sealant against heat and provides the ability to overcome the centrifugal force of a rotating tyre. PunctureSafe’s abilities & performance does not diminish with speed, distance or time.

Protects the entire inner surface of the tyre

PunctureSafe provides a coating that clings to more of the inner tyre, thereby providing protection for the tyre at all times.

Positive sealing capabilities

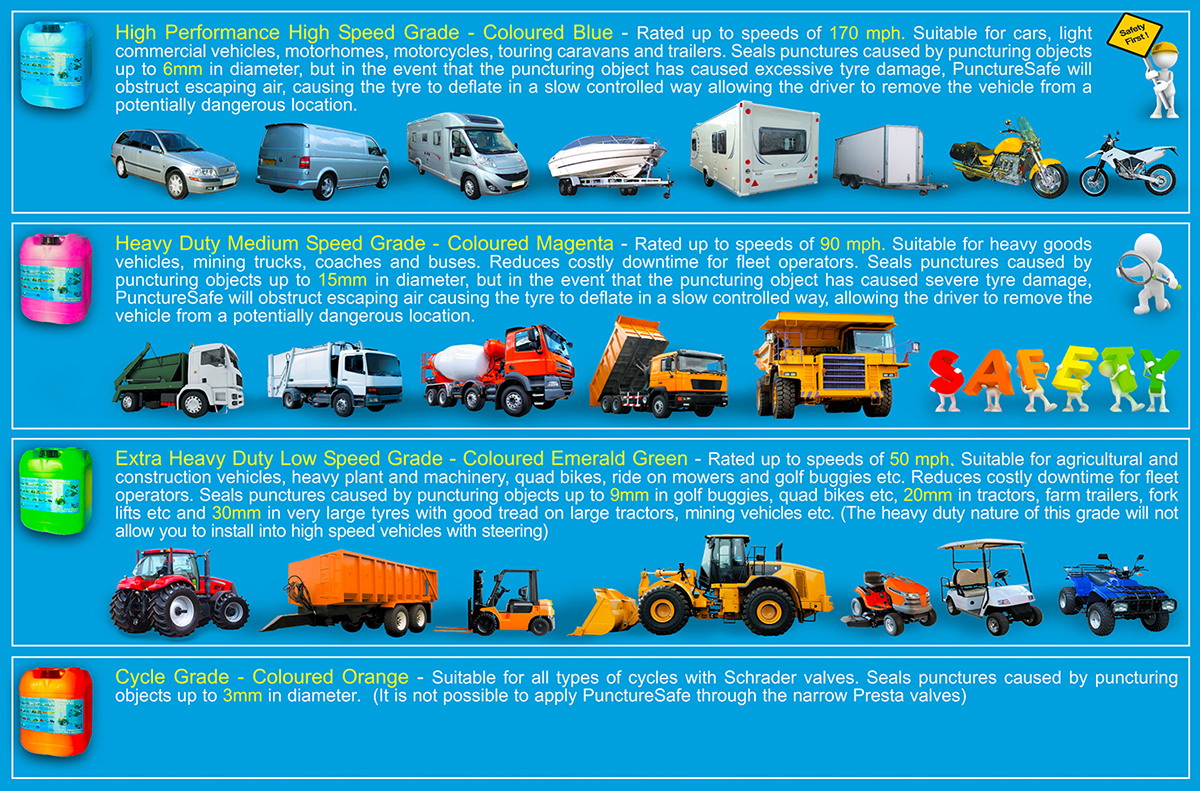

PunctureSafe seals are positive and secure, thereby transforming any tyre into a self-sealing tyre. PunctureSafe is capable of sealing tread area punctures caused by puncturing objects up to 6 mm in diameter, as long as the puncturing object has not severely damaged and/or weakened the tyre’s structural integrity. PunctureSafe cannot create a secure seal in any tyre that has major internal damage, regardless of the puncturing object’s diameter.

Water-soluble (for easy clean out)

PunctureSafe is completely water-soluble in its liquid state, and leaves no residue when rinsed with plain water. Yet it will not dissolve within a puncture after it has cured. Standard repairing procedures can be utilised without additional effort.

Protection against rust and corrosion

PunctureSafe contains a complete rust and corrosion inhibiting system that not only protects steel and alloy wheels, but in a puncture, PunctureSafe’s proprietary process will also protect steel belts. Outside contaminants are prevented from leaching back into the puncture, which would cause the steel belts to rust and the ply’s to separate. Without PunctureSafe’s protection, the contaminants would quickly destroy valuable casings.

Cannot create a balance problem

Treating a tyre with the recommended amount of PunctureSafe does not provide for an excessive amount of product to accumulate in the tread area, therefore the tyre is not subjected to a mass of substance (common with many tyre sealants) that would create an imbalance. PunctureSafe cannot create an imbalance due to the ability to evenly coat the inner surfaces of the tyre subjected to normal centrifugal force.

If the suspension is worn beyond specified tolerance, or a tyre/rim assembly is not balanced and/or trued, the abnormal centrifugal force generated will have enough gravitational force to pull PunctureSafe off the vertical surfaces and collect in the problem area thereby increasing the “existing” imbalance problem. If the problem is severe enough the driver will feel a vibration. The vibration indicates that a problem pre-existed in the tyre assembly or suspension prior to installing Puncturesafe.

Eliminates most flats and blowouts

The majority of flats and blowouts are a result of driver negligence. The number one cause being excessive heat generated from under inflation. The overheated, under inflated tyre becomes soft and can be penetrated very easily. However, under inflation creates additional problems such as tread separations, ply separations and tread ruptures. All of the above is primarily caused by porosity (natural air migration) which exists in all tyres to some degree.

PunctureSafe eliminates air migration and prevents the majority of damage created by under inflation, thereby preventing most related blowouts. The sealing capabilities of PunctureSafe are unparalleled by any tyre sealant, worldwide.

Will not void tyre warranty

Tyre manufacturers state that tyre sealants do not void their warranties unless it can be proved that the additive caused a problem to the tyre structure. PunctureSafe’s polymer composition is completely compatible with all tyre components.

Compatible with all retread methods

PunctureSafe conditions the casing and retards aging. Plus, the ability to be thoroughly cleaned out of the tyre assures no hindrance for inspection. The product is non-toxic, non-hazardous, non-flammable, does not present a disposal problem and has no compatibility problems

How Does

PunctureSafe Function Inside a Tyre?

It is very important that you understand two aspects regarding the performance characteristics of a tyre, in order to fully comprehend how PunctureSafe Tyre Life Extender/Conditioner actually functions, along with and as part of the tyre

What is rubber recovery?

Rubber recovery within a tyre, is very important in conjunction with PunctureSafe. When a tyre is punctured, the rubber is forced open by the penetrating object. The puncture is actually much smaller than the puncturing object.

Rubber has memory and it will recover to its original shape after being subjected to adverse conditions or stress factors. When the penetrating object is removed, the rubber recovers and the puncture closes (a tyre that is old, worn out and/or dry rotted will have little or no rubber recovery).

A penetrating object left in a tyre for any extended period of time causes the rubber to temporarily lose its ability to recover. After removing the puncturing object, it is recommended to immediately flex the tyre to reactivate the rubber’s memory. As the puncture closes, PunctureSafe is held in place by the strength and integrity of the tyre and will then create a positive secure seal.

What is tyre flexing?

Tyres are constantly flexing when a vehicle is driven. The weight of the vehicle, the irregular surface of the road, and the turning of the tyres create a substantial amount of flexing.

Once the puncturing object is removed, it is important for the PunctureSafe seal to be forced into and through a puncture. Once this is accomplished the seal cures and becomes a positive secure seal.

Manual tyre flexing (off the vehicle) can be accomplished by removing the puncturing object and then striking the tyre several times with a mallet around the puncture area and/or bouncing the tyre against the ground. This method creates a temporary seal that will become positive once the tyre is installed onto the vehicle and driven approximately 3 to 5 miles.

Is it necessary for you to understand tyre construction?

NO! There are many variables in tyre construction. In order for a tyre sealant to function properly the tyre sealant manufacturer must have knowledge of the sealant and tyre compatibility, plus have the knowledge and ability to perform exhaustive testing that will assure that the sealant new or used is compatible.

Compatibility and chemical composition is important when a sealant is new in order to meet Health and Safety requirements, but most importantly is what happens to the tyre sealant formulation after it has been run a few thousand miles, and exposed to the normal heat in a tyre and the shear and stress that results from the centrifugal force generated in a rolling tyre.

Most generic tyre sealants can become toxic and/or an environmental hazard. Heat build-up is an important factor and the primary reason average generic tyre sealants fail to perform as claimed.

How does PunctureSafe produce a positive/secure seal?

Once the initial driving/usage period has been attained (3 to 5 miles), Puncturesafe will be distributed over the crown area and after 1500+ miles throughout more of the inner surface of the tyre. PunctureSafe makes a very thin coating which has the ability to remain suspended on to the tyre.

It’s PunctureSafe’s proprietary process that prevents the formulation from separating and/or migrating to the tread area.

PunctureSafe is a liquid coating that conditions the inner surface and eliminates porosity and bead leaks as minute amounts of air attempt to escape. PunctureSafe continuously stands on guard to protect tyres against air loss from punctures for the tyre’s legal tread life.

When a tyre is punctured, PunctureSafe is forced against and around the puncturing object by the inner air pressure, thereby preventing air from escaping.

If the puncturing object is thrown out of the tyre by centrifugal force or is pulled out, the inside air forces PunctureSafe into the puncture and immediately stops air loss. Special fibres entwine, forming a seal, then as the rubber recovers (see rubber recovery), aided by the flexing of the rotating tyre, the inner air pressure forces the seal well into and through the puncture.

Once PunctureSafe is exposed to outside air, a unique curing process begins. The seal extends well into and through the puncture and once cured provides a seal that is impervious to water.

The cured seal, is then transposed into a positive rubberised seal, thereby protecting the inner casing and steel belts by preventing outside contaminants from leaching into the wound.

Will PunctureSafe cure or harden inside of the tyre?

People often ask “If PunctureSafe cures from exposure to outside air, then why does it not cure by the air inside of the tyre?”

As the vehicle is driven and the temperature of the tyre increases, a portion of PunctureSafe’s liquid base evaporates within the tyre’s inner air cavity, as the tyre cools, the vaporised liquid condensates back into the formula. The inside air actually becomes part of the PunctureSafe system. The sealed air chamber prevents outside air from entering or inside air from escaping. Constant air pressure resetting is not required. Tyres and air pressure should be inspected during routine maintenance.

Why does PunctureSafe not cause a balance problem?

It is extremely important to understand how PunctureSafe’s proprietary process, not found in any other tyre sealant, prevents any balance issues prevalent in the majority of other sealants.

PunctureSafe clings to the inner surface of a properly balanced and true (round) tyre. The centrifugal force that is created within a high-speed tyre actually stretches PunctureSafe much like a rubber band; however, it will not pull PunctureSafe off the inner surface of a properly balanced tyre.

A sufficiently out of round and/or out of balance tyre can create enough adverse force that could pull the coating of PunctureSafe from the tyre’s inner sidewalls. If a tyre requires an excessive amount of weights to be installed to achieve a good reading on the balancer, the tyre should be inspected for defects and corrected prior to installing PunctureSafe. PunctureSafe cannot correct an existing problem and may aggravate an adverse situation.

The proper amount of PunctureSafe for high speed vehicles has been scientifically calculated to provide the proper coating to the inner surface of the tyre, allowing for absorption into the casing, yet still maintain a reserve.

The reserve (approximately 20% of the installed amount) is extra PunctureSafe that will shift/move. Only the reserve will settle to the bottom of the tyre when the vehicle stops. The reserve constantly redistributes as the tyre rotates, thereby continually providing an even coating. Each time a puncture occurs, a small amount of reserve is used.

Ethylene Glycol is a Toxic Antifreeze –

so it is not in PunctureSafe

PunctureSafe does not contain Ethylene Glycol. It took us years to find a non glycol anti freeze which was suitable for use in a tyre sealant and that was non toxic. Ethylene Glycol is one of the most toxic substances used in tyre sealants worldwide because 2 teaspoons of Ethylene Glycol can kill an adult within 2 days. Our biggest concern was for the regular users of our tyre sealant who could be poisoned by absorption through the skin, eventually getting a build up of kidney stones (calcium oxalate crystals). Because the body cannot remove these calcium oxalate crystals in the kidneys, a build up over time could be fatal. Our other concern was for the passengers of a car breathing in the Ethylene Glycol vapours from a very hot severely damaged flat tyre placed in the boot. Also because children and pets could have access to tyre sealants that contain Ethylene Glycol and because we have a duty of care policy we considered it irresponsible to use this in our products. We have always supplied a glycol free sealant which is 100% non toxic and 95% organic.

Toxicity

Ethylene Glycol poisoning can be divided into three stages. Stage one includes central nervous system (CNS) disturbances and gastrointestinal symptoms. Stage two includes signs of cardiovascular, pulmonary, and metabolic irregularities and stage three includes renal failure brought on by the precipitation of calcium oxalate crystals in renal tubules and from the direct toxic action of oxalic and glycolic acids upon the kidneys. Safety standards in the world are not as advanced as the UK and the majority of these E/G sealants are coming in from North America.

The major danger from Ethylene Glycol is ingestion. Due to its sweet taste, children and animals will sometimes consume large quantities of it if given access to antifreeze. Ethylene glycol poisoning is a medical emergency and in all cases a poison control centre should be contacted or medical attention should be sought. It is highly toxic with an estimated LD100 in humans of approximately 1.4 ml/kg. However, as little as 30 milliliters (2 tablespoons) can be lethal to adult. For Hazardous Substance Fact Sheet, CLICK HERE.

Symptoms

Symptoms of Ethylene Glycol poisoning usually follow a three-step progression, although poisoned individuals will not always develop each stage. Stage one consists of neurological symptoms including victims appearing to be intoxicated, exhibiting symptoms such as dizziness, headaches, slurred speech, and confusion. Over time, the body metabolises Ethylene Glycol into other toxins, first to glycolaldehyde, which is then oxidized to glycolic acid, glyoxylic acid, and finally oxalic acid.

Stage 2 is a result of accumulation of these metabolites and consists of tachycardia, hypertension, hyperventilation, and metabolic acidosis. Stage 3 of ethylene glycol poisoning is the result of kidney injury, leading to acute kidney failure. Oxalic acid reacts with calcium and forms calcium oxalate crystals in the kidney. An estimated 80% of kidney stones are calcium oxalate.

Ethylene Glycol is a good anti freeze additive in a tyre sealant but that might have been OK throughout the 1960s but we think that is unacceptable today. We at PunctureSafe knowing that children/pets can have access to a tyre sealant and that unaware and untidy installers will allow the sealant soak through their skin, we decided to invest in years of laboratory research to find a non toxic alternative that would complement the sealing properties of our sealant.

During our research and development we discovered that everything available came with their own problems when added into a tyre sealant and this was probably why no manufacturer in this industry bothered to invest the huge amounts in time and money needed to find the perfect non toxic antifreeze suitable for a product going to the general public.

We did it, but it was exhaustive. We are now satisfied in the knowledge that we have a safety product that will not be harmful to the unsuspecting.

You can find us at

555 George Street, Aberdeen, AD25 3XX

Opening Hours

Monday – Saturday

(10AM – 6PM)

Call us Now

+447974312916 (Fred)

+447723328501 (Bim)

Support

info@harmonieventures.com

copyright (c) harmonieventures 2021. Powered by iBrowseo